VERTICAL FLAMELESS VENTING

VERTICAL FLAMELESS VENTING

NZ DUCT+FLEX are the only company in NZ who can offer this safety feature.

Only dust extraction filter units with VFV™ ensure, in the unlikely event of a dust explosion, the explosion pressure will vent safely up into the sky with NO FLAME emerging.

What makes filters with VFV™ so safe?

The World's Safest Filter!

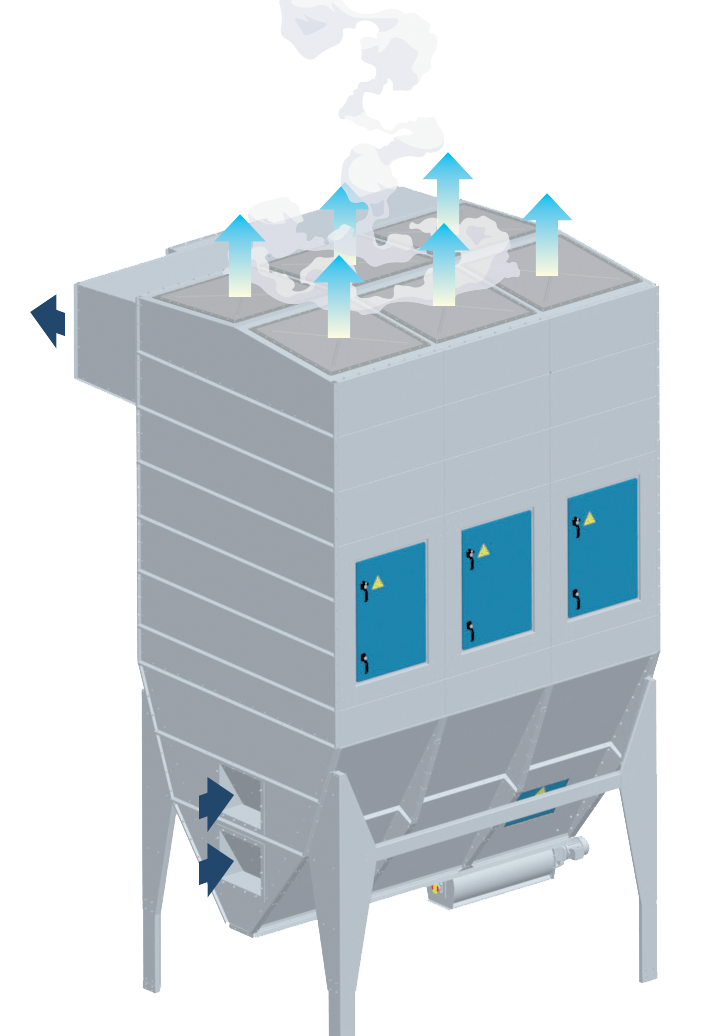

Should a filter catch fire and an explosion occur, dust extraction filters with Vertical Flameless Venting vent vertically: through the roof, via an ATEX approved explosion membrane.

Vertical Release protects the area around the dust filter unit - there is no requirement to mark off exclusion areas as required with a side-venting explosion panels, possibly saving you large areas of your car park or at least not limiting where the filter unit can be sited.

There is no fire ball: all the dust and flames are contained within the filter unit! Due to the strengthened design, the unit itself will remain intact, apart from the ATEX safety explosion release panel in the top.

Our filters from Denmark with this VFV™ technology are unique in the New Zealand, and in fact in the entire global dust extraction market.

These units have been independently tested and certified by the German FSA test house.

Ask to see the Certification or Video confirmation from an authorised test house, if you are offered a product that makes the same claims. We can provide these - others can't.

The entire filter assembly is designed to pass this test - retrofitting explosion membranes to a basic filter assembly which has not been proven to withstand an event is dangerous. The result of airborne panels and thousands of screws will be devastating to anyone in it's path should an explosion occur.

ATEX and IECEx compliant units supplied as required.

SIDE Venting explosion relief requires an exclusion zone to be marked, to be compliant. But choosing a dust collector with Vertical Venting saves this space in your site, and our filters emit NO FLAMES if a dust explosion happens.

These ATEX certified explosion relief panels are top venting as they are part of our VFV™ feature, no exclusion zone necessary - all pressure and shock waves exit vertically with no flames emitted - unique!

This top of the range SuperBlower filters uses multiple VFV™ explosion relief membranes to protect staff and anyone in the vicinity if an event is to occur. We have installed many filters with VFV™ all over NZ: in recycling, wood working, schools and other industries where our customers take safety seriously and want the latest technology rather than install a dust solution the same as those available 50 years ago.