VARIpulse Sensor Cleaning

VARIpulse™ SENSOR CLEANING

VARIpulse™ is a technology that allows us to claim the most energy efficient dust extraction filters in the world!

With more and more emphasis on understanding and declaring actual energy footprints in all industries, this VARIpulse™ feature, available on a range of our filters, will help prove companies are making energy savings. Due to these savings and resultant less wear on the filter socks, the feature also ensures the dust extraction system virtually pays for itself in a relatively short time, rather than constantly using up maintenance budgets on sock replacement every year, which simply should not be necessary in a properly sized filter unit.

Buying a dust extraction solution that incorporates VARIpulse™ is for a company with a committed policy to take environmental impact and energy saving seriously.

How does it work?

The World's most energy efficient cleaning system!

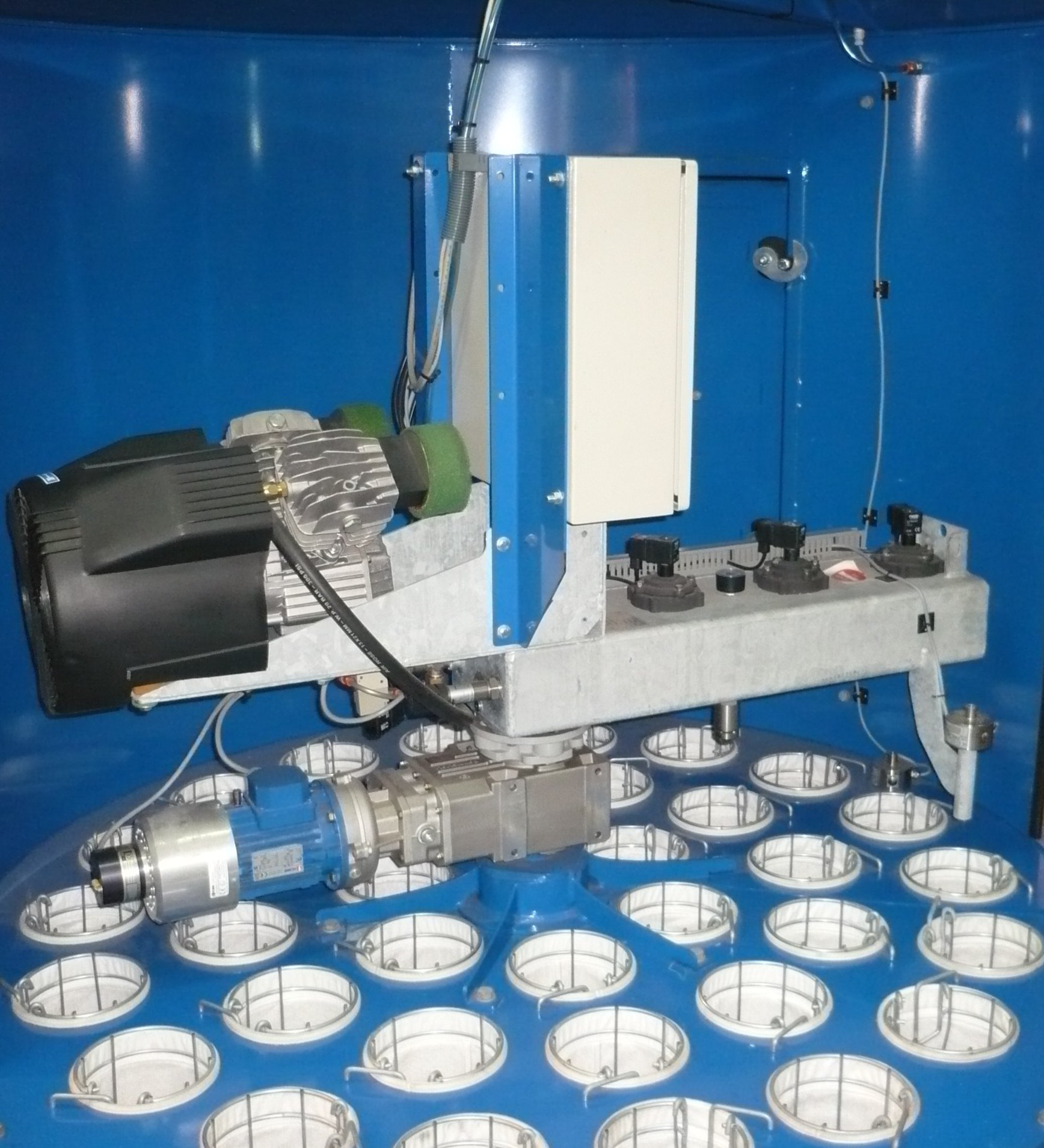

The VARIpulse™ cleaning system regulates the:

- frequency and the

- power of the pulse cleaning of your dust extraction system.

How can VARIpulse™ save you energy?

Automatic Sensor: the filter sock cleaning is controlled by an automatic sensor

- Variable Frequency, not Fixed: Cleaning only occurs when the VARIpulse™ sensors detect that the filter bags need cleaning, instead of at fixed intervals - the system used on older designed systems with out this unique feature, i.e. most other dust filters!

- Compressed Air consumption: Less energy is required to clean the bags/socks saving between 50-90% of compressed air consumption, and resulting in less load on your compressor!

- More accurate cleaning: When pulse cleaning takes place, each bag is cleaned individually. This is unique to the VARIpulse™ system, saves compressed air, and introduces the cleaning pulse exactly at the correct point above the filter sock. This ensures even cleaning for EVERY bag in the dust filter.

- Variable Pulse force: Whilst cleaning individual bags, the VARIpulse™ sensors also measure the air flow through the filter socks and adjusts the pulse forces between 1.5bar and 5bar. This save another 40-60% of compressed air using only what is necessary. Older designs use a constant 5bar.

- Longer life for parts: Because the filter socks are not being blasted with 5-8 bar continuously, they last longer: 10-15 years is common in the systems we have supplied. The socks are all uniformly cleaned and operating at maximum efficiency, the pressure loss through the filter is maintained at optimum levels, to ensure minimal load on the extraction fan and compressed air motors. The socks lasting longer and not needing changing is a huge cost saving for maintenance engineers.