DUST EXTRACTION SYSTEMS

Dust Extraction Systems

A well designed Dust Extraction System will transform your work place.

Investment in a new dust extraction system will pay for itself with benefits to staff and lower equipment maintenance.

Well designed Dust Extraction System will transform your work place

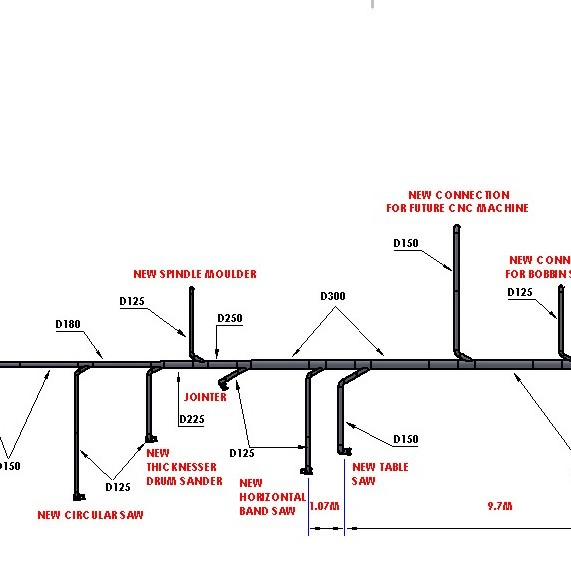

Clean, safer work areas with less downtime for maintenance is the result of our installation here

Industrial Dust Extraction Systems: Understanding Dust Extraction Systems

If you've noticed dust floating through your workspace, you've seen exactly why a dust extraction system matters. These systems work by creating negative pressure that pulls contaminated air through filtration, capturing particles before your team breathes them in.

What makes dust extraction systems work so well is how all the components come together; extraction hoods at each source, ductwork carrying dust away, and collectors capturing everything. The real key to any dust extraction system is source capture: grabbing dust right where it's created, before it spreads. This approach is far more efficient than trying to clean air that's already contaminated.

Benefits of Dust Extraction Systems

When you install a dust extraction system, you'll notice the difference quickly. The most important benefit is protecting your people as dust exposure leads to serious respiratory problems, and your dust extraction system stops those particles before anyone breathes them in.

You'll also find your facility stays cleaner with less effort. When your dust extraction system captures particles at source, they're not settling everywhere, so cleaning takes far less time. Your equipment benefits too. Dust extraction systems remove fine particles that would otherwise damage machinery, meaning fewer breakdowns and longer equipment life.

There's compliance as well. WorkSafe expects dust control, and having a proper dust extraction system shows you're serious about it. For combustible materials, your dust extraction system also prevents dangerous accumulation.

At NZ DUCT+FLEX, we've specialised in dust extraction systems for twenty years, so we've seen what a difference the right system makes.

Design of your new Dust Extraction System should be carried out by an experienced sales technician to suit your specific workplace needs

21st C Energy saving features are available is this is a priority for your company

Types of Dust Extraction Systems

Different dust extraction system setups work better for different situations.

Central Dust Extraction Systems

When you've got dust at multiple points, a central dust extraction system often makes most sense. These connect all extraction points to one collector through ductwork. Central dust extraction systems give you consistency. Every workstation gets proper extraction, and you maintain one main system.

Portable Dust Extraction Systems

Sometimes you need flexibility. Portable dust extraction systems pack everything into mobile units you can move wherever needed. They're brilliant for workshops where work moves around. Many clients combine central and portable dust extraction systems to cover all situations.

Downdraft Dust Extraction Systems

For bench work like grinding or sanding, downdraft dust extraction systems are hard to beat. They pull air through the work surface, catching particles before they float up. Downdraft dust extraction puts extraction exactly where you need it.

Cyclone Dust Extraction Systems

Cyclone dust extraction systems add pre-separation that spins heavier particles out before filters. This extends filter life significantly which is especially valuable in woodworking dust extraction where you're handling chips alongside fine dust.

Local Exhaust Ventilation: LEV

LEV is the principle behind effective dust extraction systems: capture contamination at source rather than ventilating it after it's spread.

The many components in your new dust extraction system need to ensure smooth air flow to ensure efficiency and avoid blockages

Our sales team understand air flows and duct sizing : this ensures the system we design for you will operate effectively

Dust Extraction System Components

Understanding what's in your dust extraction system helps you see why each part matters.

Extraction Hoods

Extraction hoods are where everything starts in your dust extraction system. They are positioned at each source to capture particles as they're generated. Hood design makes a huge difference to dust extraction system performance. Different jobs need different styles, from enclosing hoods to flexible extraction arms for very small amounts of dust for eg. bagging.

Ductwork

Ductwork is your dust extraction system's transport network. It needs proper sizing to keep particles moving. Too slow and dust settles, too fast wastes energy. Good dust extraction ductwork has sealed joints and smooth transitions.

Dust Collectors

The collector is the heart of your dust extraction system, separating particles for disposal or reuse. Options include baghouse filters and cartridge collectors. Modern dust extraction systems include automatic cleaning that save energy and have explosion relief as a part of their design.

Fans

Fans provide the power driving your dust extraction system. Variable drives let you adjust output to match demand, saving energy while maintaining dust extraction performance.

Dust Extraction System Design

Good dust extraction system design follows solid engineering principles.

Source capture is fundamental as it takes far less airflow to grab dust where it's made than to filter contaminated air. That's why dust extraction systems prioritise hood placement and design.

Capture velocity needs to be enough to overcome dust movement. Transport velocity through dust extraction ductwork keeps particles airborne until they reach collectors. System balancing ensures every branch of your dust extraction system gets proper airflow.

We exceed the Ministry of Education Guidelines for schools including ATEX Equipment Directive 2014/34/EU for explosive atmosphere protection

Our staff are in dusty environments from many industries all over NZ - we know our dust

Big industry installs and small Joinery workplaces can be sure they are compliant with our dust extraction solutions

Dust Extraction Applications

We've installed dust extraction systems across many industries.

Woodworking Dust Extraction Systems

Wood dust extraction systems handle everything from chips to fine sanding dust. Most use two-stage separation with cyclones first. Because wood dust burns, safety features like spark detection protect woodworking dust extraction systems.

Metal Dust Extraction Systems

Metalworking dust extraction systems face different challenges: sparks, fumes, potentially toxic particles. These dust extraction systems need spark arrestors and appropriate filter media.

Food Dust Extraction Systems

Food processing needs hygienic dust extraction systems you can clean thoroughly, plus explosion protection for high risk combustible ingredients such as flour.

School Dust Extraction Systems

School dust extraction systems require special attention to safety features recommended by Ministry of Education guidelines. Our filters exceed these.

Installation and Maintenance

Getting your dust extraction system installed properly is crucial. We plan carefully to minimise disruption and ensure every duct joint seals properly.

Regular maintenance keeps your dust extraction system performing well. Monitoring filter pressure, checking ducts for buildup, confirming fans deliver needed airflow.

Working with NZ Duct+Flex

We start every dust extraction project by understanding what you need through site visits and conversations about your challenges. From there, we design a dust extraction system that fits your situation.

We train your team for confident dust extraction system operation, and our ongoing support keeps your system performing year after year.

Compliance

Health and Safety law requires dust exposure control, and a dust extraction system provides that protection. Proper documentation shows WORKSAFE you've done things right.

Why Choose NZ Duct+Flex

Twenty years focused on dust extraction systems means we've solved problems across every industry. European partnerships give us proven dust extraction technology, while local knowledge ensures your dust extraction system suits New Zealand conditions. From first conversation through ongoing support, we make sure your dust extraction system delivers lasting value.